Quality Policy

- Production accordance with quality standards that achives the customer satisfaction and improving the quality in the all stages of production for this aim..

- To contact the customers depend on mutual trusting and achieve the customer satisfaction.

- Productivity and low-cost production.

- To achieve stable growth by human and technology investment.

- To comply with conditions of Quality Management System and provide continuance of efficiency and continual improvement. Making plans to achieve this aim.

High quality in every step...

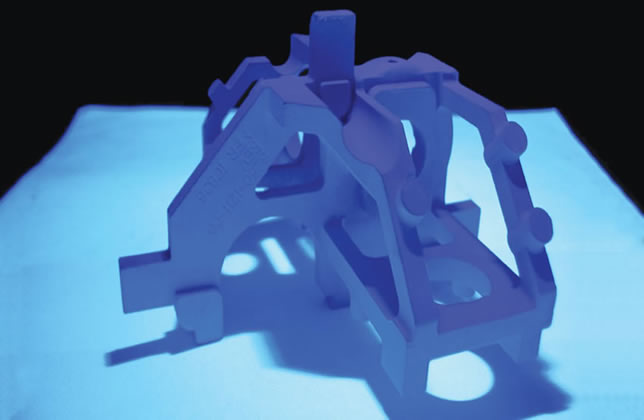

Gür Metal employs a rigorous and continuously improving quality management system that has been developed according to international standards by a dedicated team of quality engineers.

Gür Metal's approved lab units are capable of conducting metallurgical analysis, tensile test, hardness measurement, microstructure analysis and non-destructive tests: and report the test results according to quality standards required by the customer.

- ISO 9001:2008 certification (since 2000)

- AS / EN 9100: 2009certification (since 2010)

- BOEING customer approval (April 2012)

- Penetrant NADCAP Certification (May 2012)

- Heat Treatment NADCAP Certification (May 2014)

- Chemical Processing NADCAP Certification ( Feb 2017)

- Radiography NADCAP Certification (March 2017)

- Control standards: EN 2076-3, EN 3125, AIR 3380, SAE AMS 2175, SAE AMS A-21180

Our Ethical Values

- Report any pressure you get to ship nonconforming product.

- Report any counterfeit products, or suspect parts, immediately.

- Don’t falsify inspection or production records.

- Don’t accept bribes to falsify results or allow nonconforming product to shipment.

- Report any problems you see regarding products, processes or the quality system itself.

- Try to always act as a customer advocate.

- Material Analysis

- Hardness Measur

- Tensile Test

- Microstr Analysis

- NTD

- Dimensional Test